产品

- RV系列双级旋片泵

- E2M系列双级旋片泵

- nES系列单级旋片泵

- ES系列单级旋片泵

- nXDS系列干式涡旋泵

- nXLi系列干式真空泵

- EDC系列爪式真空泵

- EOSi系列喷油螺杆泵

- EH系列罗茨真空泵

- EDS系列干式螺杆泵

- GXS系列干式螺杆泵

- GV系列爪式真空泵

- T-Station涡轮分子泵小车

- STP系列涡轮分子泵

- Stokes滑阀泵

- Stokes 6罗茨泵

- D-LAB系列隔膜真空泵

- nEXPT系列分子泵站

- nEXT系列涡轮分子泵

- EDP系列化工爪式干泵

- CXS系列化工螺杆真空泵

- CDX系列化工螺杆真空泵

- HT系列油蒸汽扩散泵

- iH系列半导体真空干泵

- iXH系列半导体真空泵

- iXL系列半导体真空干泵

- EPX系列半导体真空干泵

- GX系列半导体干式泵

产品详情

简单介绍:

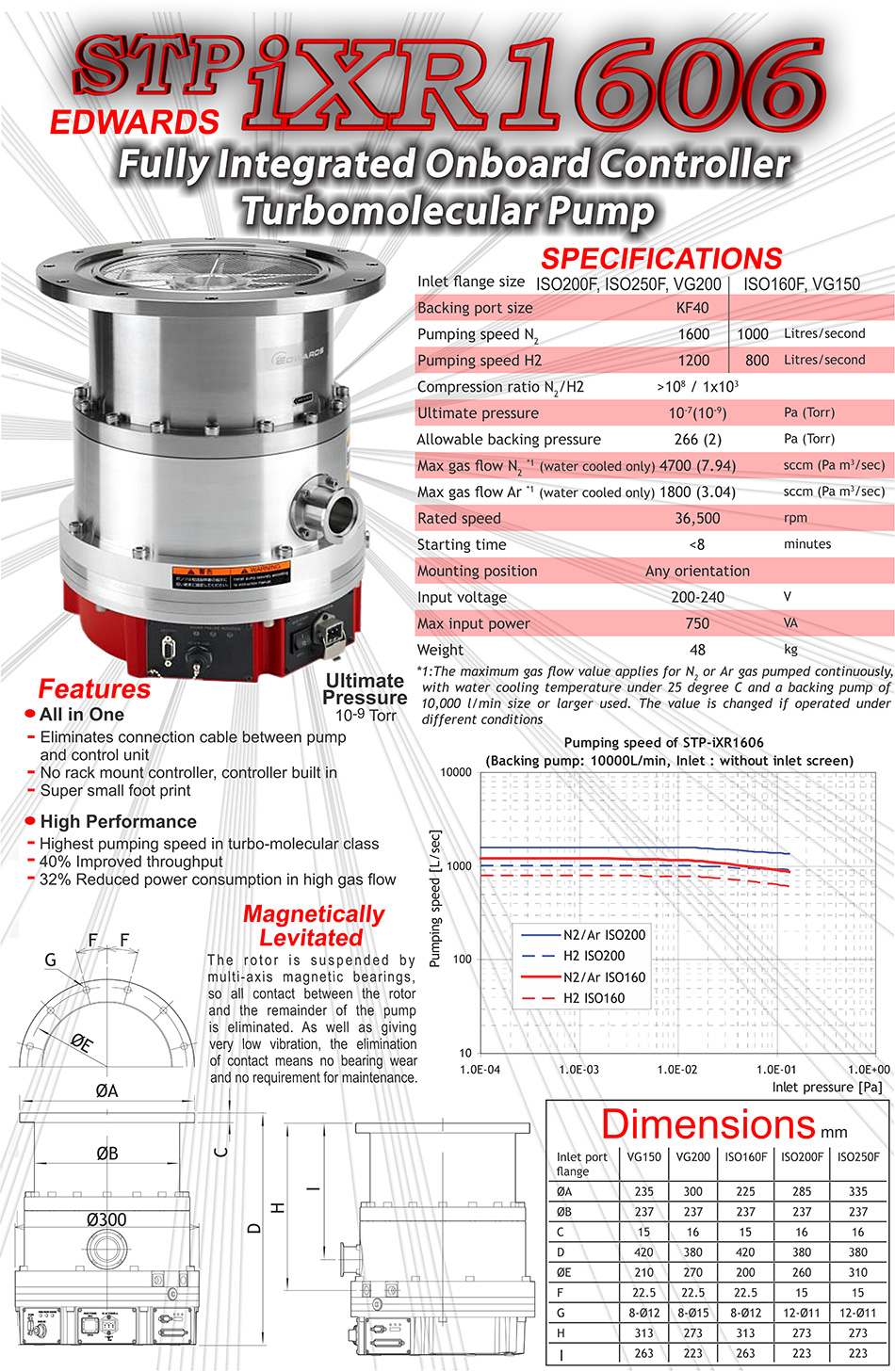

STP-iXR1606 ISO200F 爱德华磁悬浮涡轮分子泵可提供业内的性能,机载控制装置中包含新的小型电源供给。

STP-iXR1606 ISO200F 爱德华磁悬浮涡轮分子泵其设计理念与 STP-iXA2206/iXA3306 系列相同。 新的**性转子设计提高了抽取性能, 这一集成的产品易于安装且占地面积小,可作为应用工具的一体化解决方案。

详情介绍:

概述

STP-iXR1606 系列磁悬浮涡轮分子泵可提供业内的性能,机载控制装置中包含新的小型电源供给。其设计理念与 STP-iXA2206/iXA3306 系列相同。 新的**性转子设计提高了抽取性能, 这一集成的产品易于安装且占地面积小,可作为应用工具的一体化解决方案。

应用

玻璃涂层

太阳能 PVD

工业溅射

特性与优势

泵和控制器之间不需要连接电缆。

消除了传统架装式控制器的安装空间和成本。

紧凑型设计使安装更加方便,占地面积更小。

与 STP-A1603 配套时在 8” TMP 同类产品中抽速高。

使高气体流速的功耗降低了 32%。

标配端口包括 I/O 远程、RS232C、RS485、STP-Link

可选配 Profibus 和 DeviceNet

The STP iXR1606 Maglev turbo-molecular pump utilizes a magnetic bearing and motor drive system and has an ultimate pressure of 10-9 Torr. This integrated controller series can be fully interfaced with advanced controllers to operate on a wide range of applications and processes. It eliminates the need for a conventional, rack-mounted controller and interconnecting cables. The fully integrated product offers easy installation and small footprint as an all-in-one solution for all application tools. The rotor is entirely suspended by magnetic bearings so all contact between the rotor and the remainder of the pump is eliminated. As well as giving very low vibration, the elimination of contact means no bearing wear and no requirement for consequent pump maintenance. The STP iXR1606 can be connected directly to a terminal using a serial port and the STP-link Monitoring Software. The Software Displays, Rotational Speed, Motor Status, Temperature, Rotor balance status & Magnet bearing current.

MAGNETIC BEARING TECHNOLOGY:

The rotor is suspended by multi-axis magnetic bearings, so all contact between the rotor and the remainder of the pump is eliminated. As well as giving very low vibration, the elimination of contact means no bearing wear and no requirement for maintenance.

VIBRATION FREE:

Magnetic levitation of the rotor results in an extremely low level of noise and vibration. Peakto- peak vibration level is less than 0.02 μm. This amplitude remains constant throughout the life of the pump and is free from troublesome subharmonics.

OIL FREE:

All STP turbomolecular pumps are oil free. The use of magnetic bearings eliminates all hydrocarbon lubricants ensuring no contamination of the vacuum process from the turbomolecular pump. This feature is vital in industry and in surface science or high energy physics applications (where even minute degrees of contamination disrupt measurements).

MAINTENANCE FREE:

Unlike conventional mechanical bearings, magnetic levitation means there is no frictional contact, eliminating sources of wear and vibration. This feature enables STP turbomolecular pumps to run for years with virtually no maintenance, reducing annual operating costs to a minimum and ensuring maximum up-time is achieved. This maintenance free feature can be particularly beneficial on processes producing chemical or radioactive contamination.

AUTOMATIC BALANCING SYSTEM (ABS):

ABS is a unique patented development of 5-axis technology. If any rotor imbalance is introduced (by deposition of process by-products, for example), sensors in the pump detect changes in the rotor motion and compensate the magnetic bearing fields to allow the rotor to spin on its natural inertial axis. This minimises the vibration transmitted to the inlet flange. ABS works at all pump rotational speeds.

SAFETY BACKUP BEARINGS:

STP pumps have dry lubricated axial and radial mechanical bearings as safety backup bearings. These support the rotor and protect the pump in the event of a total disruption of magnetic suspension or a massive air inrush which overcomes the magnetic bearing stiffness. These high precision ball bearings are dry lubricated and are not in contact with the rotor during normal operation..

The STP iXR1606 can be used for a variety of applications including but not limited to:

STP-iXR1606 系列磁悬浮涡轮分子泵可提供业内的性能,机载控制装置中包含新的小型电源供给。其设计理念与 STP-iXA2206/iXA3306 系列相同。 新的**性转子设计提高了抽取性能, 这一集成的产品易于安装且占地面积小,可作为应用工具的一体化解决方案。

应用

玻璃涂层

太阳能 PVD

工业溅射

特性与优势

泵和控制器之间不需要连接电缆。

消除了传统架装式控制器的安装空间和成本。

紧凑型设计使安装更加方便,占地面积更小。

与 STP-A1603 配套时在 8” TMP 同类产品中抽速高。

使高气体流速的功耗降低了 32%。

标配端口包括 I/O 远程、RS232C、RS485、STP-Link

可选配 Profibus 和 DeviceNet

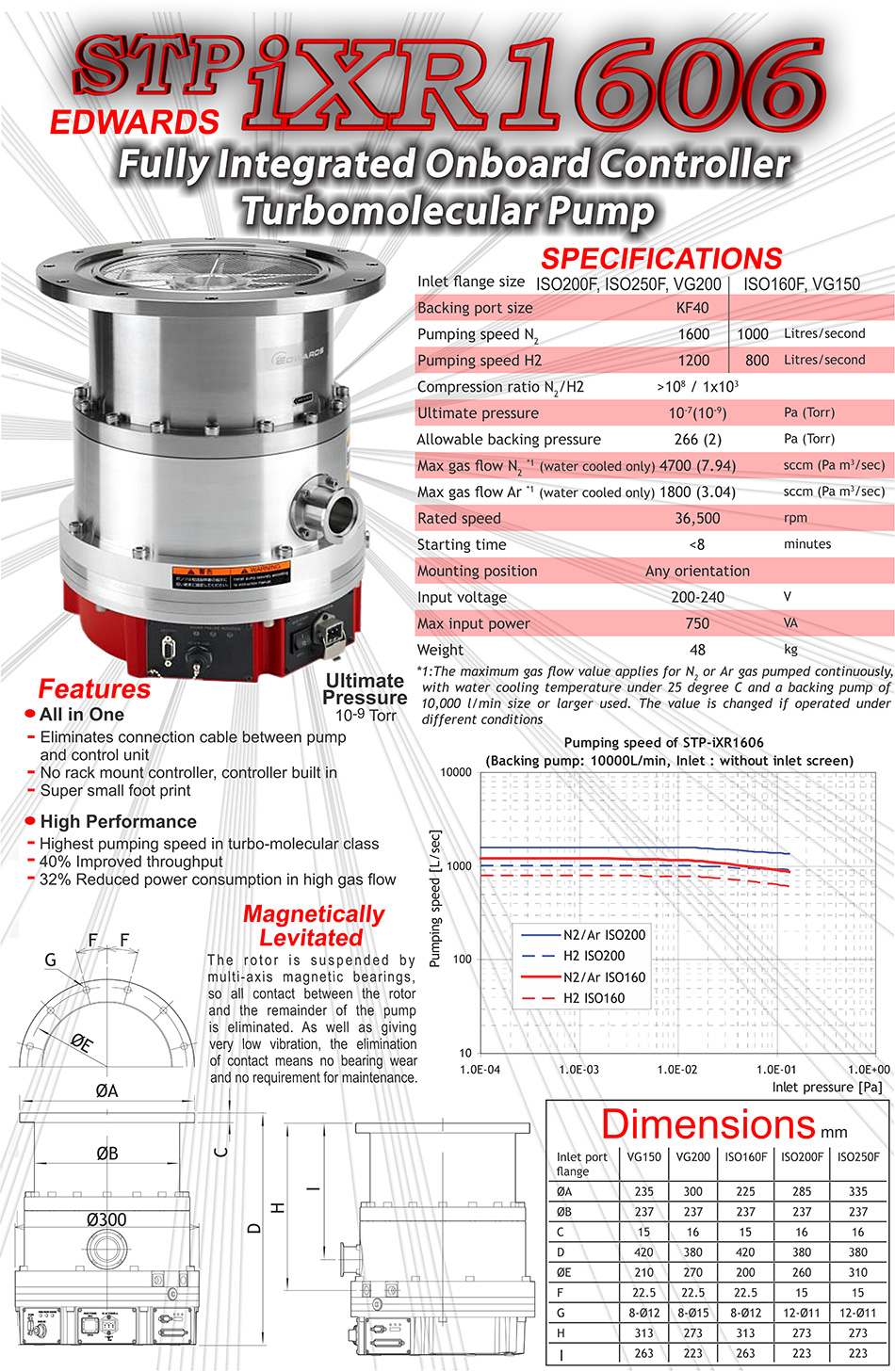

数据

| 入口法兰 | VG150 | VG200/VG250 |

|

|

ISO160F | ISO200F/ISO250F |

|

|

ICF203 | ICF253/ICF305 |

| 后备口 | KF40 | KF40 |

| 抽取速度 |

|

|

| N2 | 1000 ls-1 | 1600 ls-1 |

| H2 | 800 ls-1 | 1200 ls-1 |

| 压缩比 |

|

| N2 | >108 |

| H2 | 1 x 103 |

| 极限压力 | 10-7 Pa (10-9 Torr) |

| 允许的前级压力 | 266 Pa (2 Torr) |

| 大气流 N2(仅水冷) | 4700 sccm |

|

|

(7.94 Pam3s-1) |

| 大气流 Ar(仅水冷) | 1800 sccm |

|

|

(3.04 Pam3s-1) |

| 额定速度 | 36,500 rpm |

| 启动时间 | 8 min |

| 固定位置 | 任何方向 |

| 输入电压 | 200 至 240 (± 10) V 交流 |

| 大输入功率 | 750 VA |

| 重量 | 48 kg |

Edwards STP iXR1606 5-axis Magnetic Bearing Turbo-Molecular Pump, ISO160F Inlet, Integrated Controller and built in power supply.

Edwards PN YT790Z070.

Edwards PN YT790Z070.

The STP iXR1606 Maglev turbo-molecular pump utilizes a magnetic bearing and motor drive system and has an ultimate pressure of 10-9 Torr. This integrated controller series can be fully interfaced with advanced controllers to operate on a wide range of applications and processes. It eliminates the need for a conventional, rack-mounted controller and interconnecting cables. The fully integrated product offers easy installation and small footprint as an all-in-one solution for all application tools. The rotor is entirely suspended by magnetic bearings so all contact between the rotor and the remainder of the pump is eliminated. As well as giving very low vibration, the elimination of contact means no bearing wear and no requirement for consequent pump maintenance. The STP iXR1606 can be connected directly to a terminal using a serial port and the STP-link Monitoring Software. The Software Displays, Rotational Speed, Motor Status, Temperature, Rotor balance status & Magnet bearing current.

MAGNETIC BEARING TECHNOLOGY:

The rotor is suspended by multi-axis magnetic bearings, so all contact between the rotor and the remainder of the pump is eliminated. As well as giving very low vibration, the elimination of contact means no bearing wear and no requirement for maintenance.

VIBRATION FREE:

Magnetic levitation of the rotor results in an extremely low level of noise and vibration. Peakto- peak vibration level is less than 0.02 μm. This amplitude remains constant throughout the life of the pump and is free from troublesome subharmonics.

OIL FREE:

All STP turbomolecular pumps are oil free. The use of magnetic bearings eliminates all hydrocarbon lubricants ensuring no contamination of the vacuum process from the turbomolecular pump. This feature is vital in industry and in surface science or high energy physics applications (where even minute degrees of contamination disrupt measurements).

MAINTENANCE FREE:

Unlike conventional mechanical bearings, magnetic levitation means there is no frictional contact, eliminating sources of wear and vibration. This feature enables STP turbomolecular pumps to run for years with virtually no maintenance, reducing annual operating costs to a minimum and ensuring maximum up-time is achieved. This maintenance free feature can be particularly beneficial on processes producing chemical or radioactive contamination.

AUTOMATIC BALANCING SYSTEM (ABS):

ABS is a unique patented development of 5-axis technology. If any rotor imbalance is introduced (by deposition of process by-products, for example), sensors in the pump detect changes in the rotor motion and compensate the magnetic bearing fields to allow the rotor to spin on its natural inertial axis. This minimises the vibration transmitted to the inlet flange. ABS works at all pump rotational speeds.

SAFETY BACKUP BEARINGS:

STP pumps have dry lubricated axial and radial mechanical bearings as safety backup bearings. These support the rotor and protect the pump in the event of a total disruption of magnetic suspension or a massive air inrush which overcomes the magnetic bearing stiffness. These high precision ball bearings are dry lubricated and are not in contact with the rotor during normal operation..

The STP iXR1606 can be used for a variety of applications including but not limited to:

- Plasma etch (chlorine, fluorine and bromine chemistries) for metal (aluminum), tungsten and dielectric (oxide) and polysilicon

- Electron cyclotron resonance (ECR) etch

- Film deposition CVD, PECVD, ECRCVD, MOCVD

- Sputtering

- Ion implantation source, beam line pumping end station

- MBE

- Diffusion

- Photo resist stripping

- Crystal/epitaxial growth

- Wafer inspection

- Load lock chambers

- Scientific instruments: surface analysis, mass spectrometry, electron microscopy

- High energy physics: beam lines, accelerators

- Radioactive applications: fusion systems, cyclotrons